III类基础油和PAO对比

来源:网络

发布时间:2019-01-09

现代炼油技术的发展推动着润滑油的进步,20世纪50年代,炼油技术以溶剂精制(solvent-refining)为主,生产出来的基础油属于API-I类。虽然这种方式炼出来的基础油在今天已经处于落后的境地,但是在当时属于技术上的进步。

20世纪7、80年代,加氢技术开始发展,预示着现代炼油技术的巨大进步。加氢处理(hydroprocessing),尤其是是加氢裂化(hydrocracking),制造API-II类油,性质上比API-I类油更稳定,低温性能更好。

1993年以后,加氢异构化炼油技术(hydroisomerization)取得了长足发展,使用当代加氢异构化技术生产的API-III类油,性能已经非常接近PAO(目前最常见的合成油之一),但是价格比PAO低的多,而且可以大批量生产。由于性能非常接近,1999年,美国商业优化局(the Better Business Bureau)下的广告部裁决,API-III类油在市场上可标示为合成油。

API-III类油和PAO (API-IV类油)性能对比:

API-IV类油为PAO(polyalphaolefins),属于合成油,长期以来,PAO有着矿物油难以企及的优点,比如黏度指数(VI:viscosityindex)高,低倾点(pour point),氧化安定性(oxidationstability)好。

Ø 黏度指数高:意味着温度变化时,油的黏度稳定、变化小。

Ø 倾点低:低温下流动性好,可以在更低温度下使用、冷启动保护。

Ø 氧化安定性好:更耐高温、使用时间更长。

而当代加氢处理技术的到来,是炼油技术的巨大突破,使用加氢异构技术生产的III类油,性能接近PAO,某些方面还超过PAO,包括:添加剂溶解(additive solubility)得更好,润滑性(lubricity),抗磨能力(antiwear),这些特性都是润滑的重要方面。而黏度指数、倾点、氧化安定性则接近PAO,也就是说PAO在这几个方面比III类油有优势:

Ø 倾点(Pourpoint)

Ø 冷启动性能(Coldcrank property)

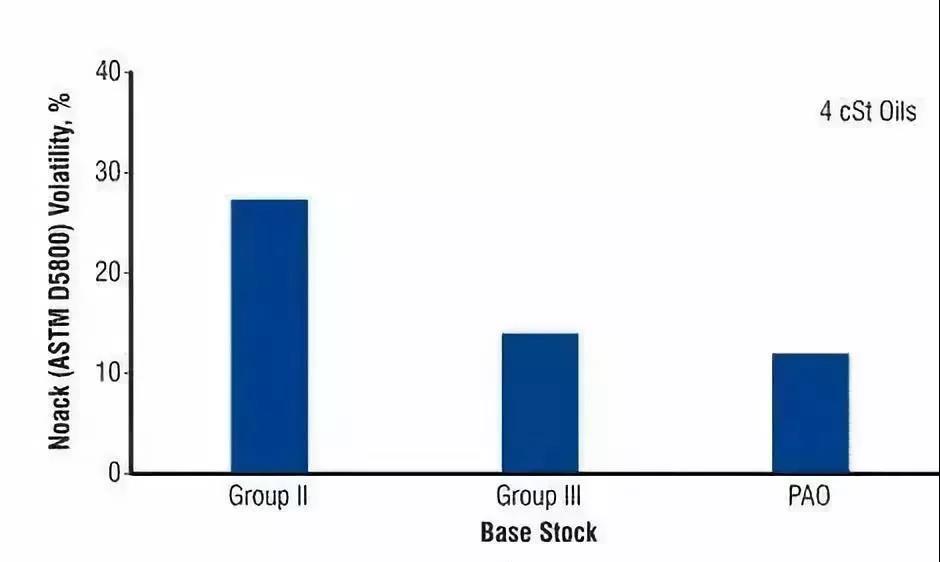

Ø 挥发度(NOACKVolatility)

Ø 氧化安定性(OxidationStability)

下面我们对这几项性能分别进行对比。

倾点是润滑油的一项重要性能指标,是润滑油的一项重要低温指标。III类油和PAO比起来,倾点上确实有差距,但是使用降凝剂(pour point depressant)可以显著减少这种差距。降凝剂可以大大降低倾点,例如,使用API-II类油调配的汽轮机油,在纯基础油的状态下,API-II类油的倾点是-12°C,使用降凝剂可以把倾点降到-36°C。而使用降凝剂,III类油倾点可以降到-45°C甚至更低。

另一个方面,PAO制成润滑油的过程中,会加入一些添加剂,这些添加剂对PAO的倾点有所影响,总体来说,III类油制成的润滑油在倾点上接近PAO,同样可以在严寒条件下使用。

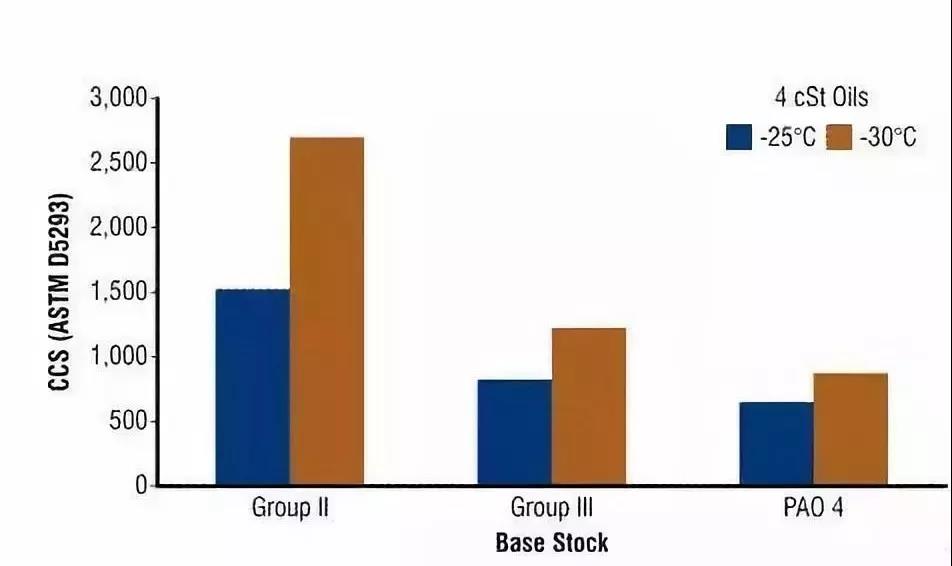

从实验结果来看,II类油低温下的粘度性能明显不如III类油和PAO稳定,PAO和III类油较接近,但PAO的低温粘度性能更稳定一些。

氧化安定性和高温稳定性是合成油最为显著的优势之一。有良好的氧化安定性和高温稳定性,润滑油可以使用更长时间。不饱和烃和芳香烃含量高,油的稳定性就差,III类油经过深度精制,脱掉了大量的杂质,芳烃含量不到1%,因此高温氧化安定性得到了提高。PAO的稳定性则主要受石蜡的残留量影响。

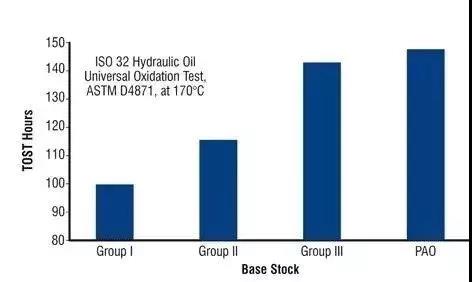

下面是四种不同类型基础油调配的液压油(同种添加剂类型),黏度为ISO 32,通用氧化测

试,试验方法ASTM D4871,测试温度170℃。对比四种液压油的氧化安定性:

图中的实验结果来自于通用氧化实验Universal Oxidation Test (ASTM D4871),对比了当油的酸值(酸值能体现润滑油的氧化程度)达到2.0时,润滑油的使用小时数。时间越短说明油变质越快。

随着催化加氢技术的进步,未来的精炼方式会提炼出更好的基础油,杂质更少、挥发率更低、使用时间更长。

还有一个趋势值得关注,就是使用天然气制作合成油(GTL:Gas to Fluids)。这类合成油的制取技术是费托合成(Fischer-Tropsch),这类合成油的黏度指数高于PAO,具有节能、长效等诸多优点,是未来车用油和工业油的理想基础油,目前已经有这类合成油上市。

其它技术也在发展,例如尝试新型的PAO制取方式,使得传统PAO的性能得到改善,但是价格因素是PAO合成油不得不面对的现实问题:制取PAO的原料价格依然居高不下,因此有人担忧,随着技术进步,PAO的市场会不会变得“小众化”。而III类油的技术发展导致炼油成本更低,III类油的性能往更高的方向发展,北美的车用油市场上,大量的合成油开始采用III类油。

从技术的角度上来说,III类油的制取技术是现代润滑油技术的一大进步,有了这项技术,润滑油“高端性能、平民价格”不再是梦,高性能润滑油的普及成为了可能。加氢技术的进步和成熟,导致II类油和III类油加速取代I类油,这一点,是设备使用者的福音。